Scales and weighing technology have evolved significantly since the mechanical dial scales that dominated usage worldwide for many years. Advanced electronics and microprocessor technology has changed how we weigh. The actual act of weighing itself hasn’t overtly changed (something is placed on a scale and a readout is shown for the weight), but rather what is done with the weight has changed dramatically in the past 30 years. Modern scales can provide you with much more than how much a product weighs. Digital scales can display whether or not the weight is over/under an acceptable target weight by means of visual or auditory signals, send data to a computer, or activate mixers, motors, and pumps through PLC and Ethernet connection. Scales now are IoT devices, meaning they can connect to the Internet for sending weight data out or providing diagnostic information about the load cells used in the scale.

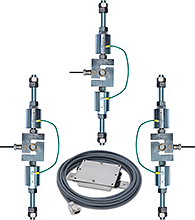

It is Cardinal Scale Manufacturing Company’s goal to help with your process applications. Our OEM (Original Equipment Manufacturer) load cells are used as solutions to integrate weighing sensors into your equipment or applications. Cardinal Scale offers load cells featuring strain-gauge type, hydraulic, or digital load cells and electronic modules that can connect to your equipment requiring a weighing function in order to be operable. Cardinal Scale takes pride in manufacturing its load cells at the company’s state-of-the-art load cell production facility at their factory in Webb City, MO.

The Cardinal Scale advantages have allowed us to provide our OEM customers with a custom, cost-effective and innovative product worldwide. We have a dedicated team of engineers, programmers, and technicians available to help reach a desired product performance. Please contact Buster Crutcher or Nick Teer in OEM Sales and visit our website if you are interested in making your product a value-added product by incorporating scale components into its design.