There is no doubt that digital weighing systems are a marked improvement over analog weighing systems due to a number of factors that will be explained in this article. Digital truck scales and digital conversion boxes both provide distinct advantages that increase efficiency, calibration, and diagnostic information communication. The following list will highlight the advantages for both and how they provide more value for those willing to make the switch to these invaluable technologies.

What are the advantages of a digital truck scale vs. a digital conversion box?

Digital truck scales offer many more diagnostic options regarding weight offset, maximum weight, cell capacity, calibration within the cell, hot and cold temperature compensation values, and temperature offsets for external temperatures. Digital truck scales feature internal calibration and all truck scale diagnostics originate from within the digital load cell itself. Digital truck scales feature load cells and load cell cables that are plug-and-play to simplify the connection process and reduce time spent terminating wiring connections. Load cells can be very easily and quickly replaced to save time and effort. Since the cell circuitry is internal to the cell, the need for a junction box and all of the accompanying wiring is eliminated. Digital truck scales also have the added benefit of remote digital monitoring, which can monitor the digital truck scale system in real time.

Digital conversion boxes have the capability of updating an analog load cell system to a digital version. If the scale owner already has an existing analog scale, then upgrading to a digital conversion system might make sense. Digital conversion boxes tend to be used more often with multiple scale systems to maximize utility of the digital conversion box system. They can be configured to a remote digital monitoring system, so they can view multiple locations at a time.

How do digital truck scales and digital conversion boxes increase efficiency over an analog system?

Digital truck scales greatly decrease the time and effort needed in diagnosing potential failures and, in turn, decreasing downtime due to cell failure. Since digital load cells are calibrated to the system before shipment, set-up time is minimal. The quick and exact digital diagnosis from remote diagnostic software reduces guesswork and time needed to find the root cause of the load cell failure. Since the system is completely digital, there is little chance of loss of signal resolution due to an analog signal. Digital truck scales feature a much simpler daisy-chain design regarding load cell wiring and load cells, and load cell cables can be replaced much quicker.

Digital conversion boxes expedite the conversion of analog information into a more manageable signal and can make diagnosing cell problems easier to detect when compared to an analog system.

How does the diagnostic process differ between technologies? Which provides more detailed alert messages?

With digital truck scales the diagnostic process begins at each load cell. A myriad of different issues can be monitored for each individual cell, which can also more quickly and accurately report cell and wiring issues. Digital cells tend to provide more diagnostic attributes relating to the cell such as cell capacity, weight and weight counts, and hot and cold temperature compensation values. Digital cells are calibrated to the weight indicator they are configured to, require little to no calibration when set up, and can be more closely monitored due to load cell serialization through diagnostic software.

A digital conversion box begins the diagnostic process within the conversion box. The digital conversion box gathers analog signals that are converted to digital signals and diagnoses cell failures when summing signals within the conversion box. Digital conversion boxes provide a panel of diagnostic attributes when checking for cell viability. The cell failure will be isolated to the faulty load cell section that includes the load cell, load cell cable, or analog section. This means less specific information is provided to the digital conversion box due to limitations within this type of system. When a cell fails, the replacement cell will be calibrated to the existing system.

Digital truck scale systems are monitored through remote software. Digital conversion boxes have the capability of being remotely monitored to diagnose problems as well. Any digital system will have an immediate advantage when giving the end user the capability of receiving alerts through the indicator and/or remote monitoring software when an issue arises.

What safeguards does either technology employ to prevent hardware/software damage?

Digital truck scales provide load cells that have potting to prevent ingress from moisture and sediment. Digital load cells have internal grounding and gas discharge to prevent damage due to surging or electrical complications. In addition, digital load cells provide a much higher information resolution due to load cells being configured to the digital truck scale indicator, eliminating loss of load cell resolution due to cell trimming within trim pots. Also, if a load cell cable is damaged, digital load cells won’t need to be replaced—just the load cell cable will be changed out. This is a distinct advantage to a digital truck scale system.

Digital conversion boxes contain wiring meant to greatly reduce the effects of voltage surges. Digital conversion boxes generally utilize either fiberglass, plastic, or stainless steel enclosures to protect internal components from moisture and sediment. Once load cells are replaced, they must be trimmed to meet fidelity within the digital conversion box.

What is required to replace a digital load cell vs. an analog load cell working in conjunction with a digital conversion box? How long does it typically take?

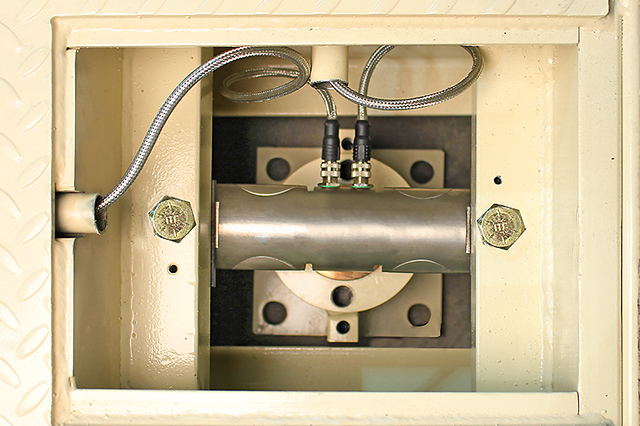

Since digital conversion occurs within the load cell in a digital truck scale system, digital load cells can be replaced quickly and easily. The scale corner must be lifted, bolts holding the load cell in place must be loosened, and the load cell cable connector must be uncoupled. Once the faulty cell has been taken out, the replacement cell will be connected to the load cell cable, bolted back into place, and then the digital load cell is back in full operation. This whole process takes approximately 5 to 10 minutes.

Digital conversion boxes monitor a system of load cells from within the conversion box. Once a load cell has been shown to possess an error, errors will be checked for the cell. The scale corner is lifted and the junction box will be opened to disconnect the five-wire cable from the load cell that must be pulled through the conduit. Then the load cell cable must be pulled back through the conduit to connect the new load cell. The wiring is then connected to the digital conversion box. After this, the junction box must be re-sealed. Special attention must be paid to prevent moisture or sediment from gathering or entering the junction box enclosure, due to the increased likelihood of leaks from within the junction box, leaks from gland connectors, and exposure from wiring load cells onto the board inside the junction box. On average, replacing an analog cell through a digital conversion box will take roughly an hour or more.

What are the connection differences between digital truck scales and analog truck scales with digital conversion boxes?

Digital load cells are daisy-chained through load cell cables linked by cable connectors. The need for wiring back to a junction box is not necessary, since the digital load cells communicate directly with the indicator. If the cables are damaged connecting to the load cell, they can be replaced without having to replace the load cell.

Digital conversion boxes are wired from the analog load cell to the junction box. Once there, each of the load cells are wired directly to a digital conversion board, secured through gland connectors on the junction box, and adjusted to calibrate the analog load cell. Analog load cell cables do not have the advantage of being monitored as they are permanently linked to the load cell. If a section of the wiring to a load cell is damaged, the load cell will have to be replaced.

Digital truck scales provide more tools from an intracellular design aspect to give scale technicians added freedom from uncertainty and lost resources. Digital truck scale load cell design provides the end user with more tools to diagnose, replace, and save valuable time when load cell issues arise. Most importantly, end users can keep their scale operating for longer, with less interruptions and smaller intervals of downtime.