Grain dump modules are a valuable option for truck scales when weighing, processing, and storing grain. Cardinal Scale’s grain dumps are built for expediting the offloading process of grain from semi-tractor trailers to maximize efficiency and increase safety. These grain dumps are built to withstand high-volume weighing and repeated exposure to highly-acidic environments beset by grain and moisture exposure. Thousands of bushel loads per hour can be unloaded quickly and safely, flowing directly through the truck scale platform while weighing the entire process.

Grain dumps can be utilized on either concrete deck or checkered steel deck truck scales. Safety requires placement of the grain dumps to be centrally located on the vehicle scale so there is exterior structural strength, but customers dictate the general position of the grating to meet their individualized needs. If a steel deck truck scale is being purchased, the grating design is positioned on the scale deck to be directly supported on the inside of Cardinal Scale’s truck scale I-beams that run longitudinally across the scale. This allows weighing and off-loading to be safe and meet the needs of that location’s weighing restrictions.

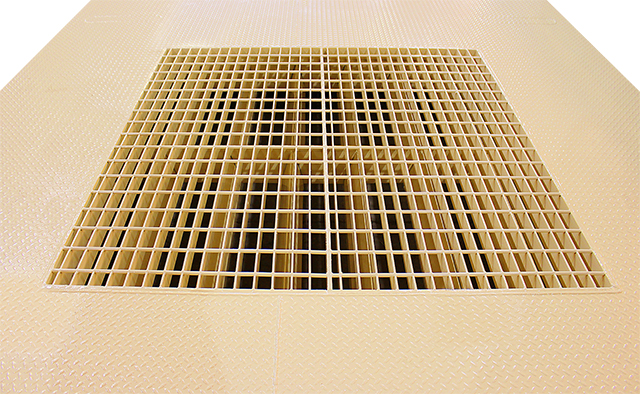

Just like Cardinal Scale’s truck scale decks come in a variety of lengths and widths, so do the grating modules utilized on truck scales. The most commonly used size for grating is four feet long by three feet wide, but the grain dump size is flexible based on customer specifications and the size of the truck scale. Larger or smaller grating sizes can be customized to meet the specifications of the trucks used on a particular farm. Some grain dumps can run the whole length of the scale deck!

Cardinal Scale’s steel grating provides high-quality protection while weighing a loaded truck scale. Cardinal Scale’s grates feature either three- or four-inch thick grating to provide the highest in deck resiliency and safety when loading and processing grain products. If a truck will be driving on top of the grating, a thicker grating material will be needed. Grating spacing is also dependent on the customer’s specifications and the type of grain being processed. Cardinal Scale’s grating is designed to provide easy flow-through when dumping grain into storage, providing quick dispensation of loaded grain products.

Customers also get the option of permanently affixing the grain dump grating to the truck scale or making the grating removable. Due to grating thickness and spacing, the scale’s CLC (Concentrated Load Capacity) will not be affected by grating that is permanently affixed, but removable grating will have minor CLC rating effects.

Cardinal Scale not only offers grating, but can also provide additional implements to aid in processing grain when off-loaded from trucks. Cardinal Scale builds customized steel rings that attach to chutes that can be placed beneath the grating on a truck scale, aiding the flow of grain to underground tank systems or hoppers. The high-quality steel rings aid in the organization of grain distribution for conveyor systems used for grain tanks and hoppers. Wasted grain is minimized, providing a great savings tool for grain processing operations.

Cardinal Scale’s grain dumping system allows farmers and co-ops many tools when processing grain products. Turning a truck scale into a grain processing implement offers a huge advantage to grain processors. Time spent weighing and separately off-loading grain is no longer necessary, giving farmers an advantage needed to save valuable time during harvest seasons.

To inquire more about the useful features and specifications needed for a certain scale project, please contact Cardinal Scale: (800) 441-4237.